UTILIZING SANCHAR PRODUCTS IN MANUFACTURING INDUSTRY

The manufacturing industry is a diverse economic sector dedicated to the production of tangible goods through various processes, including raw material transformation, assembly, and fabrication. It encompasses a wide array of sectors, such as automotive, electronics, textiles, pharmaceuticals, and more. Manufacturers use machinery, technology, and skilled labour to create products that range from consumer goods to industrial equipment.

This sector is vital to economies worldwide, contributing significantly to GDP, employment, and innovation. It often drives economic development, technological advancements, and international trade. The manufacturing industry continuously evolves, embracing automation and sustainable practices to meet consumer demands and global challenges.

DIGITAL RELAY RADIO

Problem Statement

-

Manufacturing industries like road and bridge construction units often operate across vast and changing locations. They require continuous long-distance communication, which conventional VHF licensed bands with specific location-based licenses cannot accommodate.

Solution

-

To address this challenge, we recommend the use of Digital Relay Radio (DRR) systems. DRR offers a versatile, license-free solution for seamless long-distance communication in dynamic construction environments. These systems provide reliable, mobile, and wide-reaching communication, ensuring that manufacturing units can maintain efficient coordination and safety measures irrespective of their ever-changing work sites. Offer clear audio, extended range, encryption, and data sharing capabilities. They are vital in noisy construction sites & in areas of underground settings like tunnels, basements etc.

DIGITAL RELAY RADIO APPLICATIONS

For Wide Area Manufacturing Operation & Civil Construction

PTT Over Cellular RADIO

Problem Statement

-

Manufacturing companies with multiple units spread over 200 to 500 kilometres face a challenge in establishing point-to-point communication due to range limitations of licensed and license-free radios, including DRR systems.

Solution

-

To overcome this hurdle, we recommend the adoption of Push-to-Talk over Cellular (PoC) radios coupled with PoC to analog conversion systems. This innovative approach leverages cellular networks, allowing seamless long-distance communication between distant manufacturing units. PoC technology offers flexibility, cost-effectiveness, and expansive coverage, ensuring efficient coordination and information exchange across geographically dispersed facilities, addressing the specific communication needs of such multi-location manufacturing companies. POC (Push-to-Talk over Cellular) radios are used in the manufacturing industry for instant communication, improving coordination, safety, and efficiency among workers across large factory floors or remote locations.

HOW A POC RADIO SYSTEM WORKS

PTT Over Cellular APPLICATIONS

For Those with nationwide Manufacturing House & Civil Construction Group

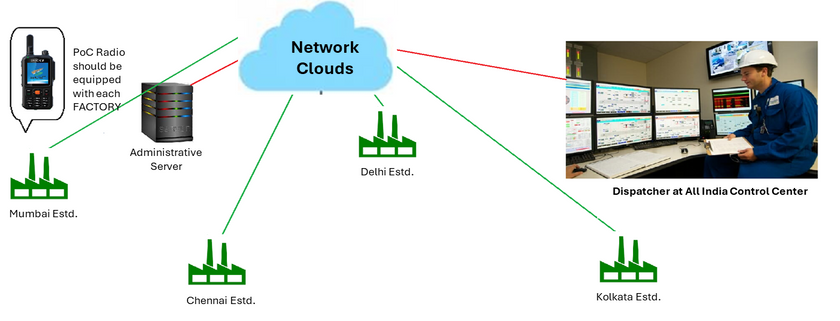

Nation Wide All The Factory Establishment could be connected by

SANCHAR POC RADIO SYSTEM

PTT Over Cellular

Push-to-Talk over Cellular (PoC) integrates individual instant communication into the global GSM network, where each PoC radio requires a SIM card for network identification.

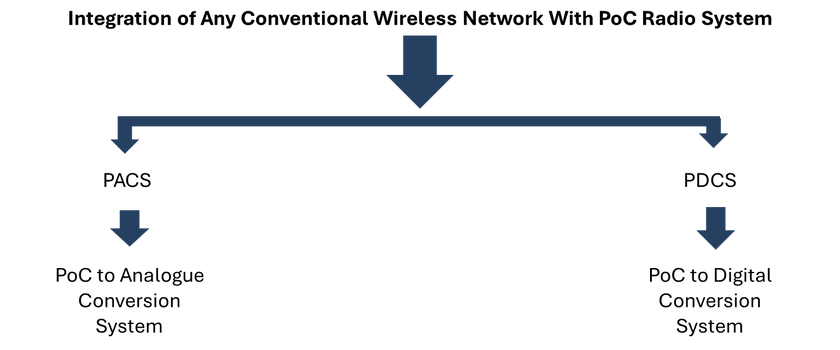

However, for manufacturing units with existing short-distance point-to-point networks developed over decades, transitioning to PoC for long-distance communication can be impractical. Sanchar has introduced an innovative solution, "PACS" (PoC to Analogue System) and "PDCS" (PoC to Digital System), bridging the gap.

These systems enable seamless communication between legacy networks and the modern PoC network, ensuring efficient long-distance communication while preserving existing infrastructure.

ALTERNATIVE TO A VIEW POC RADIO SYSTEM

PTT Over CellularAPPLICATIONS

-

The Above Two Local VHF or UHF, Either in Analogue or Digital mode network may be at any location could be connected by this system.

LICENSE FREE RADIO

Problem Statement

-

In a basic manufacturing industry, efficient cost and time management are paramount. Internal communication on the move within the unit is crucial, especially for units spanning multiple areas. However, traditional communication methods may be inadequate.

Solution

-

To address this challenge, implementing License-Free Walkie-Talkies is a cost-effective solution. They operate within the 446.0-446.2MHz frequency range with a maximum RF output of 500mw. These walkie-talkies provide efficient short-range communication, reducing licensing costs without compromising effectiveness.

BODY WORN CAMERA

Problem Statement

-

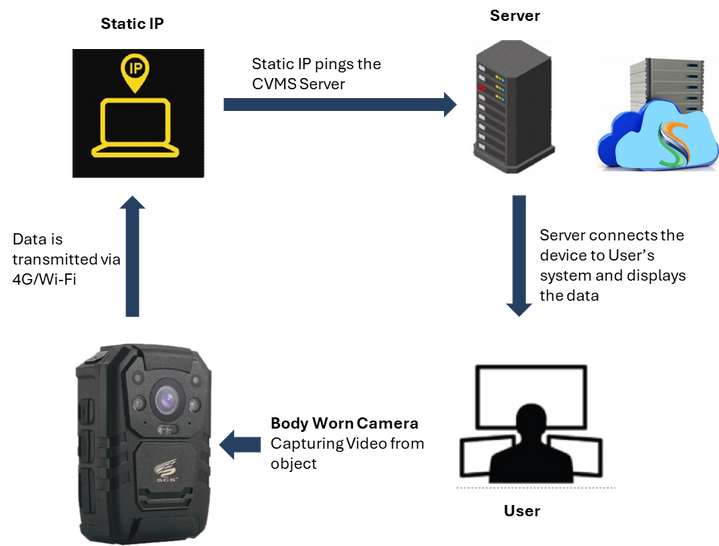

To address this issue, Sanchar Communication System has introduced the "Body Worn Camera" solution. This technology enables dynamic surveillance and recording of all processes. By equipping personnel with body-worn cameras, manufacturing units can ensure real-time documentation, minimize errors, enhance accountability, and facilitate efficient troubleshooting. Document work processes, aid in training, and promote accountability in manufacturing and construction. They serve as evidence, improve safety protocols, and discourage misconduct.

Solution

-

Manufacturing units face critical challenges in their stores and logistics departments, where errors in handling raw materials and finished goods can be detrimental. Rectifying such mistakes becomes exceedingly difficult without a documented record.

BODY WORN CAMERA APPLICATIONS

-

Loading / Unloading Videos are being Captured By SANCHAR BWC’s

FOR LIVE MONITORING INTEGRATION IN BWC

BREATH ALCOHOL ANALYZER

Problem Statement

-

To address this problem, the implementation of Sanchar's Breath Alcohol Analyzer is proposed for staff administration. By integrating this technology into the workplace, manufacturing and construction industries can promote a safer and more productive environment, reduce accidents, enhance employee well-being, and mitigate the negative impact of alcohol addiction on their operations.Breathalyzers ensure a sober workforce in industries with heavy machinery. They help with compliance, prevent accidents caused by impaired workers, and maintain a safe work environment.

Solution

-

Manufacturing and construction industries face the persistent challenge of managing labourers with alcohol addiction issues. Such employees often disregard instructions, impacting productivity and safety. Moreover, a significant portion of their income is spent on alcohol consumption.